PRODUCTS FOR INDUSTRY

We serve clients from the offshore, onshore, shipbuilding, construction, and industrial sectors — from the initial concept to final completion.

PRODUCTS FOR INDUSTRY

We serve clients from the offshore, onshore, shipbuilding, construction, and industrial sectors — from the initial concept to final completion.

Which Markets Do We Operate In?

We supply and install products for the shipbuilding, fish processing, and metalworking industries.

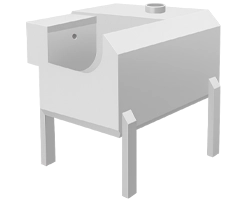

What Products Do We Supply for Fish Processing?

We offer complete equipment for fish processing plants on land and at sea.

Stainless steel machines

PLATFORMS AND STRUCTURAL DECKS

Equipment and accessories

STAIRS, RAILINGS, AND SAFETY FEATURES

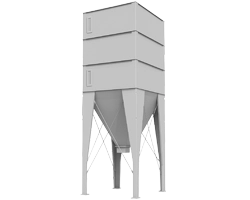

Steel and aluminum silos

What Products Do We Supply for the Shipbuilding and Offshore Industry?

We supply steel and aluminum products and semi-finished products dedicated to the shipbuilding and offshore sectors.

STEEL SHEETS AND BLANKS

Doors and hatches

BOLLARDS AND MOORING POSTS

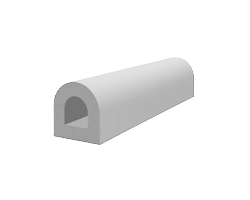

QUAYSIDE PROTECTION

Containers

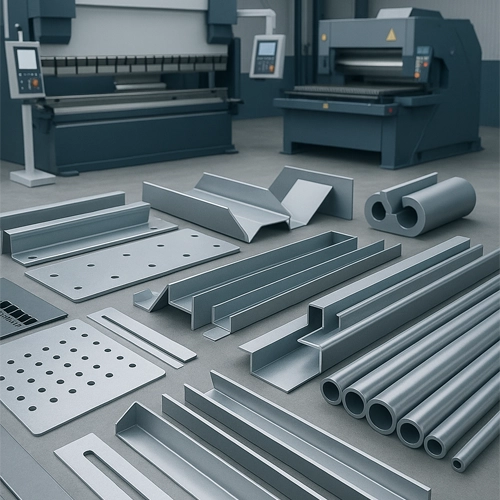

What Types of Metal and Plastic Processing Do We Perform?

We supply almost any components and semi-finished products for your production process using modern machinery parks.

CNC cutting

CNC bending

Rolling

Machining

Welding

What Types of Surface Treatment Do We Use?

We prepare and protect surfaces according to the individual needs of your project, tailored to operating conditions and requirements.

Shot blasting

Hot-dip galvanizing

Painting

Grinding

Polishing

Shot blasting

Hot-dip galvanizing

Painting

Grinding

Polishing

See Our Projects

Why Work with MBProff?

Individual approach and comprehensive service

MODERN MACHINERY PARK

Wide range of products

FLEXIBLE DELIVERY TIMES

High-quality materials

Competitive prices

Technical and design consultations

Frequently Asked Questions

A Conversation Is the First Step

Let’s talk about your needs — completely with no obligation:

Leave us your contact details, and we’ll get back to you shortly.

* The data you provide will be used solely for the purpose of handling your inquiry and will not be shared with third parties.

We approach your projects and needs individually and comprehensively.

We invite you to cooperate with us.